While 3D printing may seem like a cutting-edge technology, it has actually been around for over 30 years. Its evolution has been nothing short of transformative, especially in the realm of LCD 3D printing. This technology offers numerous advantages and is being applied across a wide range of industries, from dental and industrial to jewelry making.

Let’s explore the benefits and diverse applications of LCD 3D printing, showcasing how it’s shaping the future across various fields.

_____________________________________________________________

3D printing — though it may sound intimidating to some — has actually been around for over 30 years. The journey began in 1983 when Chuck W. Hull invented the first resin printer, revolutionizing manufacturing and various other global industries. This initial 3D printer utilized stereolithography (SLA) techniques, where a laser traces each point in a single layer of resin, instantly hardening it into plastic.

Over the years, SLA 3D printing has evolved, giving rise to other techniques like DLP and LCD printing.

As 3D printing technology advanced, affordable 3D printers began to emerge, making it possible for hobbyists to design and create their own projects. This expansion has led to a surge in 3D printing applications, including medical and dental printing, industrial manufacturing, model prototyping, jewelry design, and more.

Now, let’s delve into the advantages of LCD 3D printing and explore its wide variety of applications!

Advantages of LCD 3D Printing

Affordable

The widespread availability of LCD screens at economical prices has significantly contributed to making resin 3D printing more affordable and accessible to the general public. In LCD 3D printing, an LED light source works in tandem with an LCD screen to control the light pattern. The LED light passes through the LCD screen, which generates an image of each layer, and this light is then absorbed by the resin, solidifying an entire layer at once.

Phrozen has been at the forefront of LCD 3D printing innovation with its ParaLED technology, where an array of LED chips projects light through an LCD screen for precise and efficient printing. Phrozen’s 3D printers, priced between $199 and $2,300, offer fast and affordable solutions for users at all levels.

As 3D printers become more affordable, it is now easier than ever for individuals to purchase and store a 3D printer at home, enabling them to start printing projects even in remote areas.

Fast Turnaround

With 3D printing technology, designers and makers can rapidly transform ideas and concepts into tangible prototypes and models. LCD 3D printers, in particular, are capable of producing these models at a fraction of the cost associated with traditional manufacturing methods. This efficiency allows for the creation of multiple 3D models in a single day, making it possible to print out several items at once.

The reduced production time means consumers can produce the items they need or want right at home, on their own schedule. Whether it’s a household item like a doorknob or a wrench, a 3D printer can create these objects quickly, saving both time and money by eliminating the need for a trip to the store.

Speed & Efficiency

3D printers are capable of creating models at unprecedented speeds. With resin printers, parts and prototypes can often be completed overnight in a process known as rapid prototyping, whereas traditional manufacturing methods might take 1-2 weeks or more for production. Once you’ve designed your model or prototype, you can use 3D printing software to slice it and then print out multiple identical parts in a single run.

For instance, the Phrozen Sonic Mini 4K can print a single layer in just 2 seconds, allowing your models to be ready in mere hours.

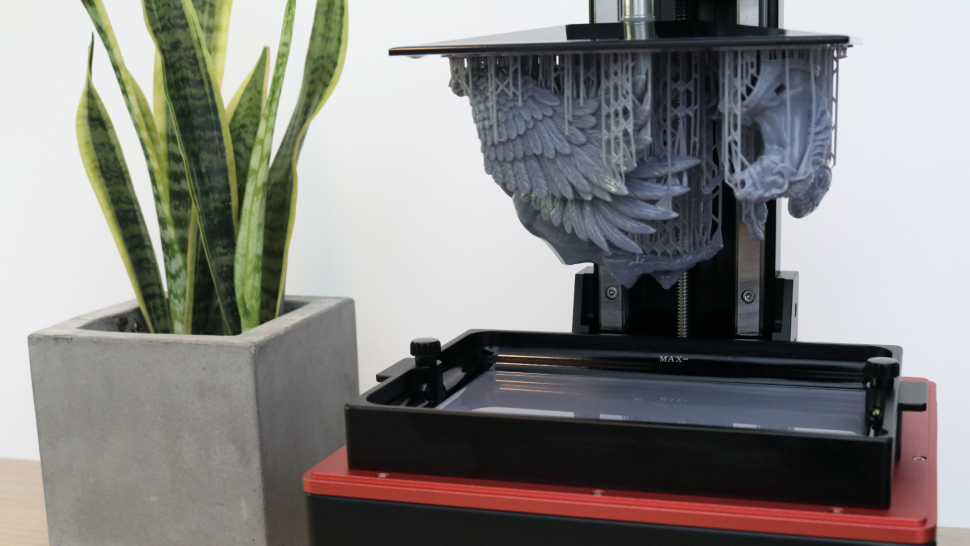

Producing Complex & Intricate Designs

LCD 3D printers empower creators to craft complex shapes and intricate designs that would be difficult or impossible to achieve with traditional manufacturing methods. This technology allows artists and designers to bring their creative visions to life, producing elaborate works that can be easily printed at a lower cost, often using less material than conventional methods.

Moreover, LCD 3D printers enable the production of custom-made items rather than mass-producing batches, offering greater flexibility and personalization. For example, the Phrozen Sonic Mini 4K delivers ultra-high-resolution printing, capable of capturing the finest details of your exact designs.

Applications of LCD 3D Printing

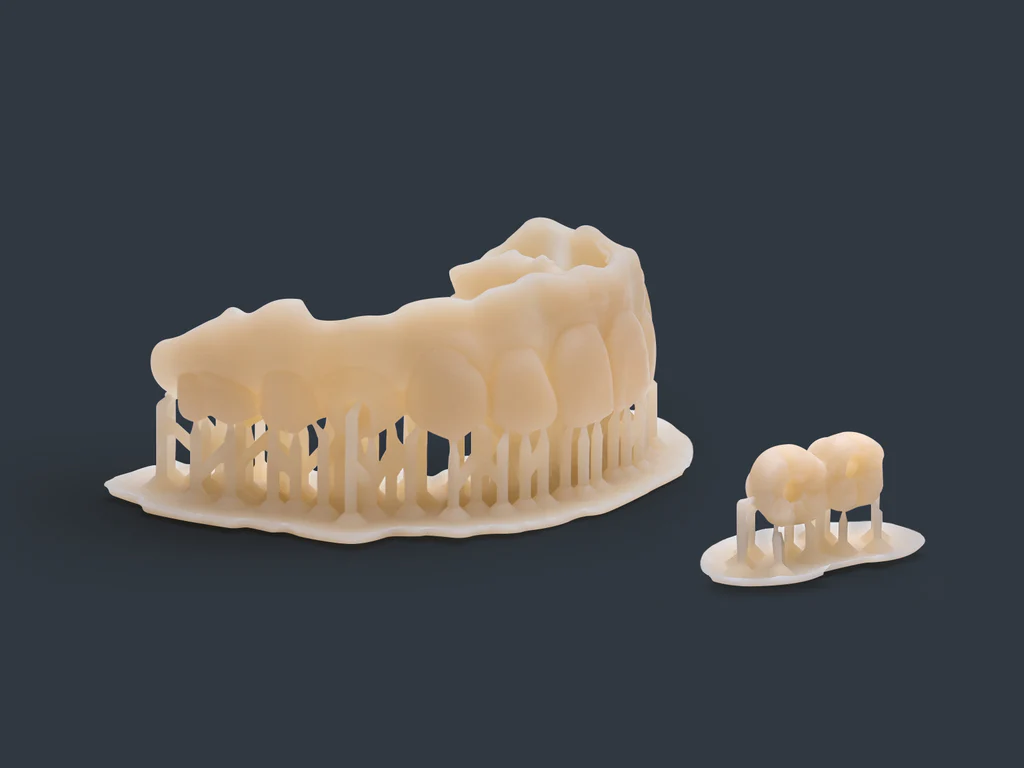

Dental Applications

The medical field has seen significant advancements thanks to the growth of the 3D printing industry, particularly in the production of implants, prosthetics, dental molds, and more, all tailored to meet the specific needs of each patient. In dental care, 3D printing has revolutionized the process of creating tooth crowns and precise dental molds. By simply scanning a patient’s teeth, dentists can generate an accurate 3D model, which can then be used to print dental molds with ease.

If any adjustments are needed in the design, they can be made effortlessly using software like Exocad, and then prepared for printing using slicer software such as Formware. Previously, dentists relied on injection molding for each patient, a process that was both time-consuming and expensive. Any errors would require the entire process to be restarted, and the cost of dental implants for a single tooth could range from $3,000 to $6,000.

Phrozen offers a range of dental 3D printers, including the Sonic XL 4K 2022 and Sonic 4K 2022, at affordable prices. These printers enable dentists to create custom fits for their patients using cost-effective and time-saving techniques, significantly boosting productivity.

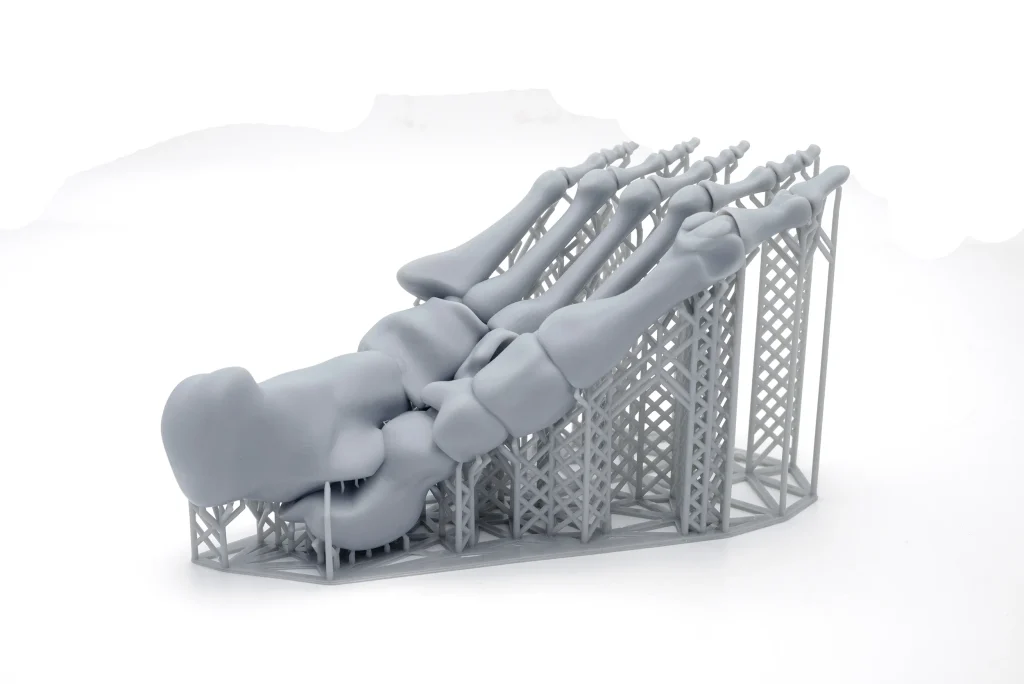

Industrial Applications

3D printing has also gained widespread adoption in industrial sectors such as automotive, manufacturing, and robotics. LCD 3D printers are particularly valued in these industries for their ability to produce parts and prototypes with high precision and accuracy—qualities that are crucial for industrial applications. The strength and durability required for these parts can be achieved by pairing a 3D printer with the appropriate resin.

Traditional methods like injection molding can be costly and time-consuming, often requiring hundreds of dollars and several weeks to produce a single mold. In contrast, LCD 3D printing can produce parts and prototypes, such as components for aircraft engines and mechanical parts, within hours.

For industrial applications, Phrozen offers printers like the Sonic XL 4K, Sonic 4K, and Transform, priced between $1,400 and $2,700. For optimal results, these resin 3D printers can be paired with resins such as Phrozen Rock Black, Onyx Rigid Pro410, Aqua-Green, or Nylon Tough.

Jewelry Applications

through 3D printing. One of the key benefits of jewelry 3D printing is the ability to produce individual pieces at a low cost. This technology can be used both for creating prototypes and directly manufacturing final jewelry pieces. If you’re interested in using jewelry 3D printing for vulcanized rubber molding,

Since LCD 3D printers can flash an entire layer at once, makers can efficiently print multiple rings or intricate jewelry designs in a single batch. This allows for the creation of detailed and complex jewelry pieces quickly and affordably.